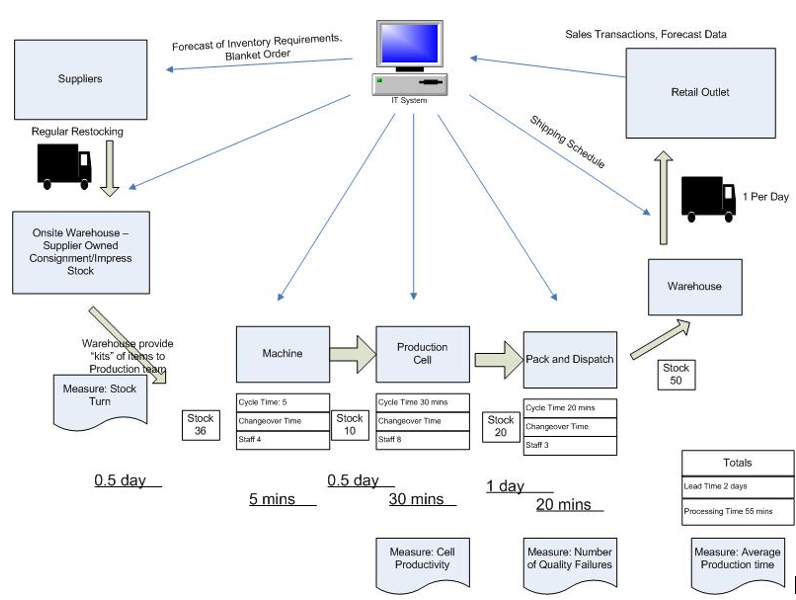

Value stream mapping is a lean manufacturing or lean enterprise technique used to document, analyse and improve the flow of information or materials required to produce a product or service for a customer.

Value stream mapping is a paper and pencil tool that helps you to see and understand the flow of material and information as a product or service makes its way through the value stream. Value stream mapping is typically used in Lean, it differs from the process mapping of Six Sigma in four ways:

- It gathers and displays a far broader range of information than a typical process map.

- It tends to be at a higher level (5-10 boxes) than many process maps.

- It tends to be used at a broader level, i.e. from receiving of raw material to delivery of finished goods.

- It tends to be used to identify where to focus future projects, subprojects, and/or kaizen events