The implementation of coordinated and clearly defined production systems is critical to the success of any manufacturing operation. The cost drivers and therefore cost saving is derived from the production environment. In the absence of proper documentation and adequate control of the production floor, there is huge potential for a company to experience high losses, the risk of poor on-time delivery performance and customer complaints due to quality concerns.

For SAS, NARAD Consulting (Pty) Ltd is proposing that we will investigate and address the following areas within the production environment.

- Development of standard times for man and machine using synthetic times

- Development of Standard Operating Procedures (SOPs) through the involvement of key staff of SAS

- Development of control sheets to capture data relating to

- Downtime

- Throughput

- Scrap

- Rework

- Absenteeism

- The development of visual management boards to represent the items listed above

- The development of electronic systems to capture data and graphically represent the data for management on a daily basis

- The implementation of lean manufacturing principles for problem solving

- 5 Why

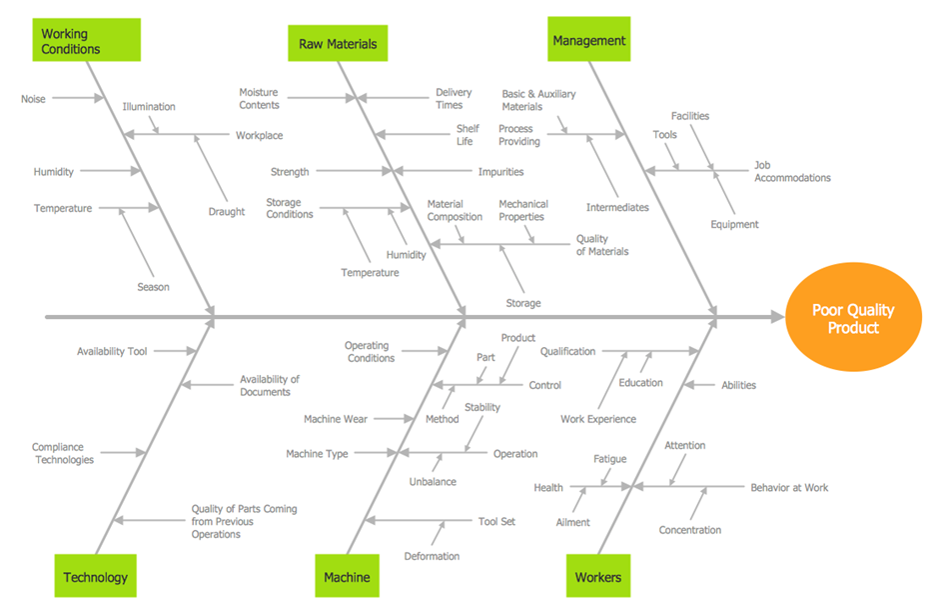

- Fishbone diagram