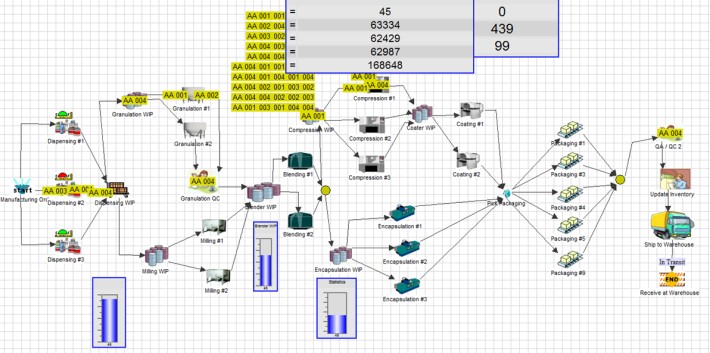

In developing the layout of the factory, NARAD Consulting (Pty) Ltd will develop process flow diagrams for the production and related environments. This will emanate from the simulation analysis of the layout. The aim will be to define the manner in which material will flow onto the line as well as along the production floor.

This will include the definition of quality control gates, hold points and materials handling locations. This definition will assist in optimising the flow of the process. Using the simulator we will be able to analyse the path that a component follows through the factory. Using methods of optimisation we will endeavour to reduce the travel of the component and also create a path wherein the component is flowing in a straight line with sub-assemblies being fed onto the main production line. This process will also involve the use of line balancing techniques in order to create a V-Profile that will take into consideration the most critical processes or machines.

The process flow analysis will also assist in determining the manpower requirements per process and will assist in the labour costing per section. This is one method of accounting for the labour expenses per department.